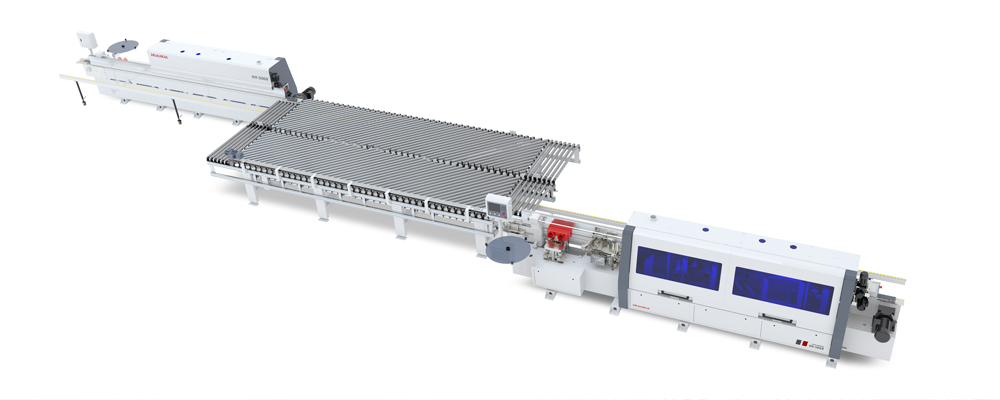

The furniture production line must do more than just assemble parts—it must use materials wisely. HUAHUA CNC’s smart solution, developed in their Foshan facility with 19 years of expertise, excels here. Trusted by over 5,000 clients worldwide, this furniture production line pushes panel utilization to 95%, a key advantage for businesses aiming to reduce waste and boost profits.

Software Integration for Precision Planning

At the heart of its efficiency is seamless compatibility with furniture design software. When a designer finalizes a cabinet or shelf design, the furniture production line’s central system imports the data instantly, analyzing dimensions and shapes to plan the most efficient cutting patterns. This integration ensures that even custom, irregularly shaped pieces are nested in a way that minimizes gaps between cuts. For example, a batch of small drawer fronts and large cabinet sides can be arranged on a single panel to avoid wasted space—something manual planning struggles to achieve consistently.

Intelligent Nesting for Every Workpiece

The line’s CNC nesting stations are engineered to handle both standard and complex shapes. Using advanced algorithms, they arrange cuts to maximize panel usage, even when processing mixed orders. This is particularly valuable for custom furniture manufacturers, where each project might require unique sizes. The furniture production line adjusts on the fly, ensuring that even last-minute design changes don’t lead to excessive waste. Over time, this adds up to significant material savings, especially for high-volume operations.

Real-Time Adjustments to Reduce Scrap

Unlike static production lines, HUAHUA’s furniture production line monitors material usage in real time. If a panel has an imperfection, the system automatically adjusts cutting patterns to work around it, salvaging otherwise unusable material. It also tracks scrap rates, providing data to managers that can be used to refine designs or purchasing decisions—further optimizing material use.

Conclusion

HUAHUA CNC’s furniture production line is a game-changer for material efficiency, leveraging software integration and intelligent nesting to reach 95% panel utilization. It turns raw materials into profitable products with minimal waste, making it an essential tool for cost-conscious manufacturers.