In modern industrial settings, dry, clean compressed air is not merely a convenience but a critical utility for numerous processes. From intricate manufacturing to sensitive pharmaceutical production, the quality of compressed air directly impacts efficiency, product integrity, and even equipment longevity. Central to achieving this quality is the effective removal of moisture, a task expertly handled by compressed air dryer systems.The compressed air dryer manufacturers like Lingyu emphasizes the crucial factors that drive informed decision-making.

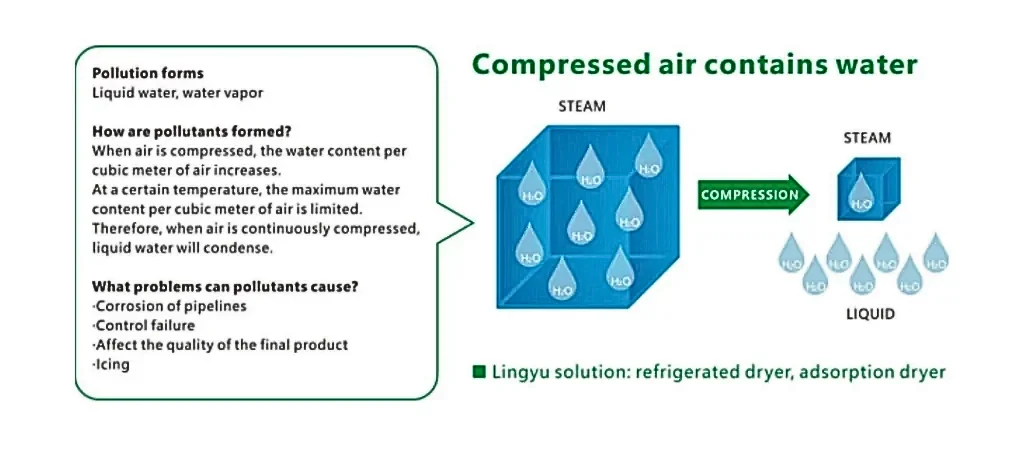

The significance of a compressed air dryer cannot be overstated. Untreated compressed air contains water vapor, which, when cooled, condenses into liquid water. This moisture can lead to a cascade of problems including corrosion of downstream equipment, contamination of end products, increased maintenance costs, and reduced pneumatic tool lifespan. Therefore, understanding how to properly select a compressed air dryer is paramount for any operation relying on compressed air.

Understanding the Different Types of Compressed Air Dryers

The first step in compressed air dryer selection involves recognizing the various technologies available, each suited for different applications and dew point requirements. Lingyu, a prominent name among compressed air dryer manufacturers, offers a diverse range of solutions, as highlighted on their products page.

Refrigerated Air Dryers: These are perhaps the most common type of compressed air dryer. They work by cooling compressed air to condense water vapor, which is then separated and drained. Refrigerated dryers are energy-efficient for applications requiring a pressure dew point typically in the range of 2°C to 10°C. They are widely used in general manufacturing, automotive, and woodworking industries. The ease of maintenance and relatively lower operating costs make them a popular choice for many facilities.

Desiccant Air Dryers (Adsorption Dryers): When lower dew points are required, desiccant dryers become the preferred option. These dryers utilize a desiccant material, such as activated alumina or molecular sieve, to adsorb water vapor from the compressed air. Desiccant dryers can achieve very low pressure dew points, often as low as -20°C to -40°C. They are crucial for highly sensitive applications found in pharmaceuticals, food processing, electronics manufacturing, and environments with sub-freezing temperatures. Desiccant dryers come in various configurations, including heatless, heated (blower purge, external heated), and heat of compression types, each offering different energy consumption profiles and regeneration methods. The selection process for these dryers often depends on the balance between desired dew point and operational expenditure.

Membrane Air Dryers: These dryers use selective permeation membranes to separate water vapor from compressed air. While typically offering higher pressure dew points than desiccant dryers, they are excellent for small, low-flow applications, hazardous environments, or where electricity is not readily available. Their compact size and lack of moving parts make them a low-maintenance solution for specific niches.

Key Considerations for Compressed Air Dryer Selection

Lingyu‘s insights on “How to Select a Compressed Air Dryer” underscore several critical factors that guide the decision-making process. These considerations ensure that the chosen compressed air dryer not only meets current demands but also offers long-term efficiency and reliability.

1. Required Air Quality and Dew Point: This is perhaps the most fundamental factor. The application dictates the maximum allowable moisture content, expressed as a pressure dew point. Critical applications, such as painting, medical devices, or pneumatic instrumentation, demand very low dew points, often necessitating a desiccant dryer. Less sensitive applications might be adequately served by a refrigerated compressed air dryer.

2. Inlet Air Conditions: The temperature and pressure of the compressed air entering the dryer significantly influence its performance. Higher inlet temperatures and pressures place a greater load on the dryer. Compressed air dryer manufacturers provide performance data based on standard conditions, and adjustments must be made for actual operating parameters.

3. Flow Rate (CFM/m³/min): The volume of compressed air to be treated is crucial. The dryer must be sized to handle the maximum expected flow rate of the compressed air system. Undersizing a compressed air dryer will result in inadequate drying, while oversizing can lead to unnecessary energy consumption and capital expenditure.

4. Energy Efficiency: Operating costs are a significant component of a dryer’s total lifecycle cost. Different dryer types and configurations offer varying levels of energy efficiency. For instance, cycling refrigerated dryers can save energy during periods of lower compressed air demand, while heatless desiccant dryers consume a portion of dried air for regeneration. Lingyu, like other reputable compressed air dryer manufacturers, emphasizes energy-efficient designs to minimize operational expenses.

5. Environmental Conditions: The ambient temperature and humidity of the installation site can affect dryer performance, especially for refrigerated models. Extreme conditions may necessitate specific dryer designs or additional pre-treatment.

6. Maintenance and Serviceability: The ease of maintenance, availability of spare parts, and service support from compressed air dryer manufacturers are important practical considerations. Regular maintenance ensures optimal performance and extends the lifespan of the equipment.

The Role of Compressed Air Dryer Manufacturers

Reputable compressed air dryer manufacturers like Lingyu play a vital role beyond just producing equipment. They offer expertise in system design, provide technical support, and continuously innovate to improve dryer performance and energy efficiency. Their comprehensive product lines, such as those detailed on Lingyu’s products page, demonstrate a commitment to meeting diverse industrial needs. When considering a compressed air dryer, consulting with these manufacturers or their authorized distributors can provide invaluable insights and ensure the optimal solution is chosen. Their experience in various industries enables them to recommend the most suitable technology and size, taking into account specific operational parameters and future expansion plans.

Conclusion

Effective compressed air dryer selection is a strategic decision that directly impacts the reliability, efficiency, and cost-effectiveness of compressed air systems. By carefully evaluating dew point requirements, inlet conditions, flow rates, energy efficiency, and environmental factors, organizations can make informed choices. Partnering with experienced compressed air dryer manufacturers like Lingyu, who offer a robust range of solutions and expert guidance, is essential for navigating the complexities of this selection process. Ultimately, investing in the right compressed air dryer is an investment in the long-term health and productivity of an entire operation, safeguarding equipment, ensuring product quality, and reducing overall operational costs.