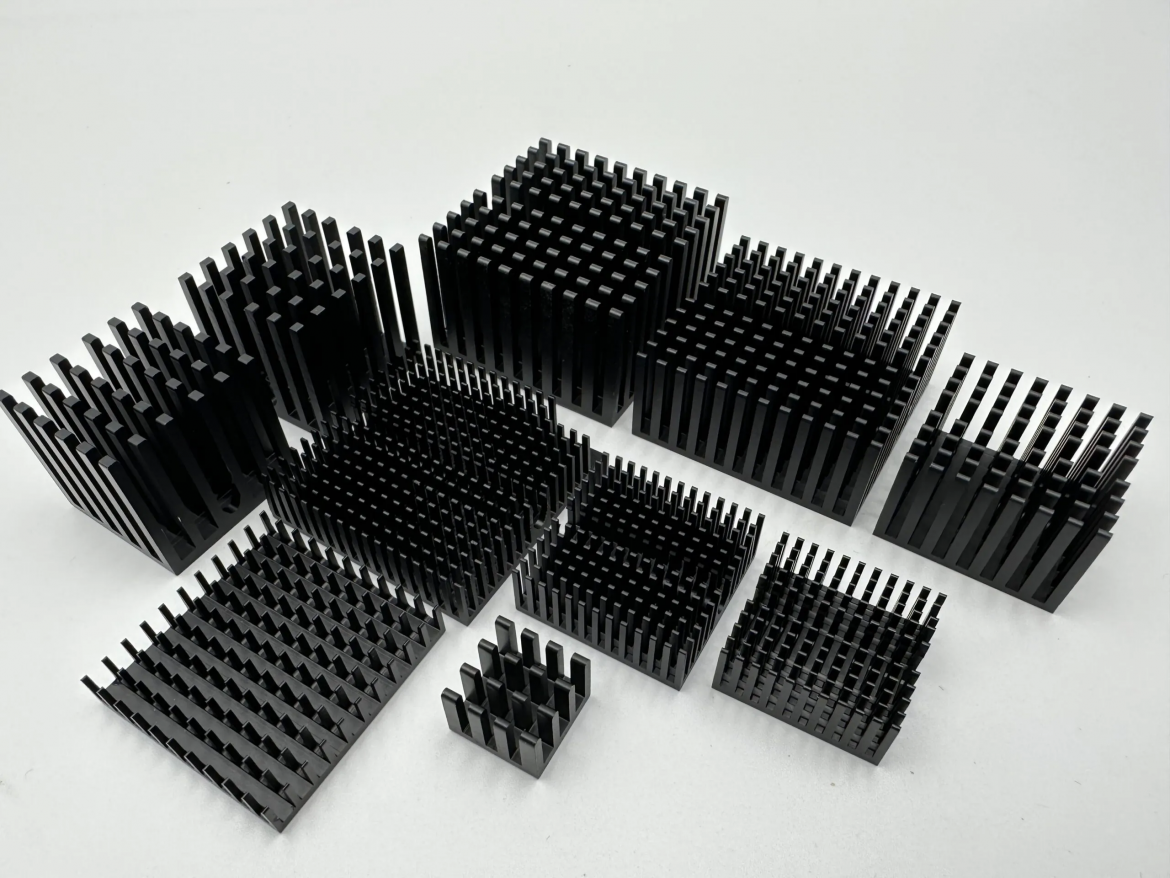

Choosing the right BGA heatsink is a crucial decision for any business involved in the design and manufacturing of high-performance electronic systems. With the increasing demand for compact, efficient thermal solutions, particularly for Ball Grid Array (BGA) packaged components, understanding the key factors that influence heatsink selection is vital. BGA heat sinks play an essential role in ensuring optimal performance and longevity of critical components such as CPUs, GPUs, chipsets, and FPGAs. This article delves into the pivotal factors to contemplate when selecting the ideal BGA heatsink for your electronic applications.

Understanding BGA Heatsinks: The Need for Effective Thermal Management

BGA heatsinks are engineered to address the thermal challenges presented by high-density electronic components. They fit seamlessly into tight spaces while providing efficient heat dissipation to maintain optimal operating temperatures. By effectively managing heat, BGA heatsinks not only prevent thermal throttling but also enhance system reliability and extend the lifespan of the components. For businesses looking to integrate BGA packages into their designs, understanding the unique properties and specifications of BGA heat sinks is critical to making informed decisions.

Key Factors Influencing BGA Heatsink Selection

Several factors should influence the selection of a BGA heatsink, ensuring that it meets both thermal and physical requirements for your specific application.

1. Thermal Performance: The primary purpose of a BGA heatsink is to dissipate heat efficiently. When selecting a heatsink, it’s crucial to evaluate its thermal conductivity and overall heat transfer capabilities. This can be quantified through parameters such as thermal resistance (°C/W), which measures how effectively the heatsink can dissipate heat away from the BGA component. A lower thermal resistance indicates better performance, enabling the component to operate within safe temperature limits.

2. Size and Form Factor: Given that BGA-packaged components often reside in tight spaces, the form factor of the heatsink is another critical consideration. The heatsink must fit seamlessly with the PCB layout without obstructing adjacent components. Businesses need to assess the available area for the heatsink, ensuring compatibility with the specific BGA package dimensions. Dingmetal offers a range of customizable BGA heatsinks designed to meet various form factors, providing flexibility for diverse applications.

3. Material Selection: The material used in a BGA heatsink significantly affects its thermal performance, weight, and cost. Common materials include aluminum and copper, each with distinct advantages. Aluminum heatsinks are lightweight and cost-effective, making them a popular choice for many applications. However, copper heatsinks offer superior thermal conductivity, ideal for high-performance scenarios where efficient heat management is paramount. Companies must weigh the pros and cons of each material based on their specific performance requirements and budget constraints.

Consider Operational Environment and Use Cases

Evaluating the operational environment is another vital factor in selecting a BGA heatsink. Understanding the conditions the heatsink will endure—such as temperature fluctuations, humidity, and potential exposure to contaminants—can profoundly influence the material choice and design features. Additionally, companies should consider the use case of the electronic device. For instance, consumer electronics may have different thermal requirements compared to industrial applications. Custom BGA heat sinks from Dingmetal can be tailored to fit the precise needs of various environments and applications.

Strategic Choices for Enhanced Thermal Management

Selecting the right BGA heatsink requires careful consideration of multiple aspects to ensure effective thermal management and the reliability of high-density electronic components. By evaluating thermal performance, size, material selection, and environmental factors, businesses can make strategic choices that enhance the efficiency and longevity of their products. As a trusted partner, Dingmetal provides high-quality BGA heatsinks designed to meet the evolving demands of the electronics industry. Investing in the ideal BGA heatsink is not merely a technical decision; it is a proactive measure toward ensuring performance excellence and customer satisfaction in today’s competitive market.